The future of construction

Valuing history and architectural integrity through adaptive reuse

Extending the lifespan of buildings is a particularly sustainable strategy with social, environmental, and economic benefits. Resource consumption and CO₂ footprint are reduced, cultural heritage is preserved, and characterful spaces that honor history are realized.

Resource-saving revitalization

Building within existing structures not only allows for the preservation of the original building form and extension of its lifespan but also enables the creation of exemplary models for resource-efficient construction.

"Using what’s there already rather than building something new is known to be the best way to save gray energy and reduce land sealing. And so, we tried it out on ourselves."

This sums up Wolfgang Rieder's motivation to revitalize a decommissioned bus garage for the new Rieder headquarters. Not only was the existing building preserved, but numerous other components were reused and recycled. By building within existing structures, Rieder saved around 1000 tons of CO₂ compared to constructing a new building, while also creating a model for resource-efficient circular construction.

Can concrete facades be sustainable?

In order to make a contribution for future generations, Rieder is taking comprehensive steps to further advance ecologicalization. This is achieved, among other things, through new material combinations, the radical reduction of waste and the extension of the life cycle of products. With a catalogue of measures and a concrete roadmap, the company is working on producing and operating with a CO₂-positive balance by 2030.

We have identified the levers where we can intervene. Now we are implementing our plan, evaluating the results and developing them further.”

This is how Wolfgang Rieder summarizes the roadmap for his company's journey to climate neutrality. The facade specialist relies on the zero waste strategy: 1/3 substitution, 1/3 more efficient processes, 1/3 offset measures.

Pioneering achievement through years of research and development

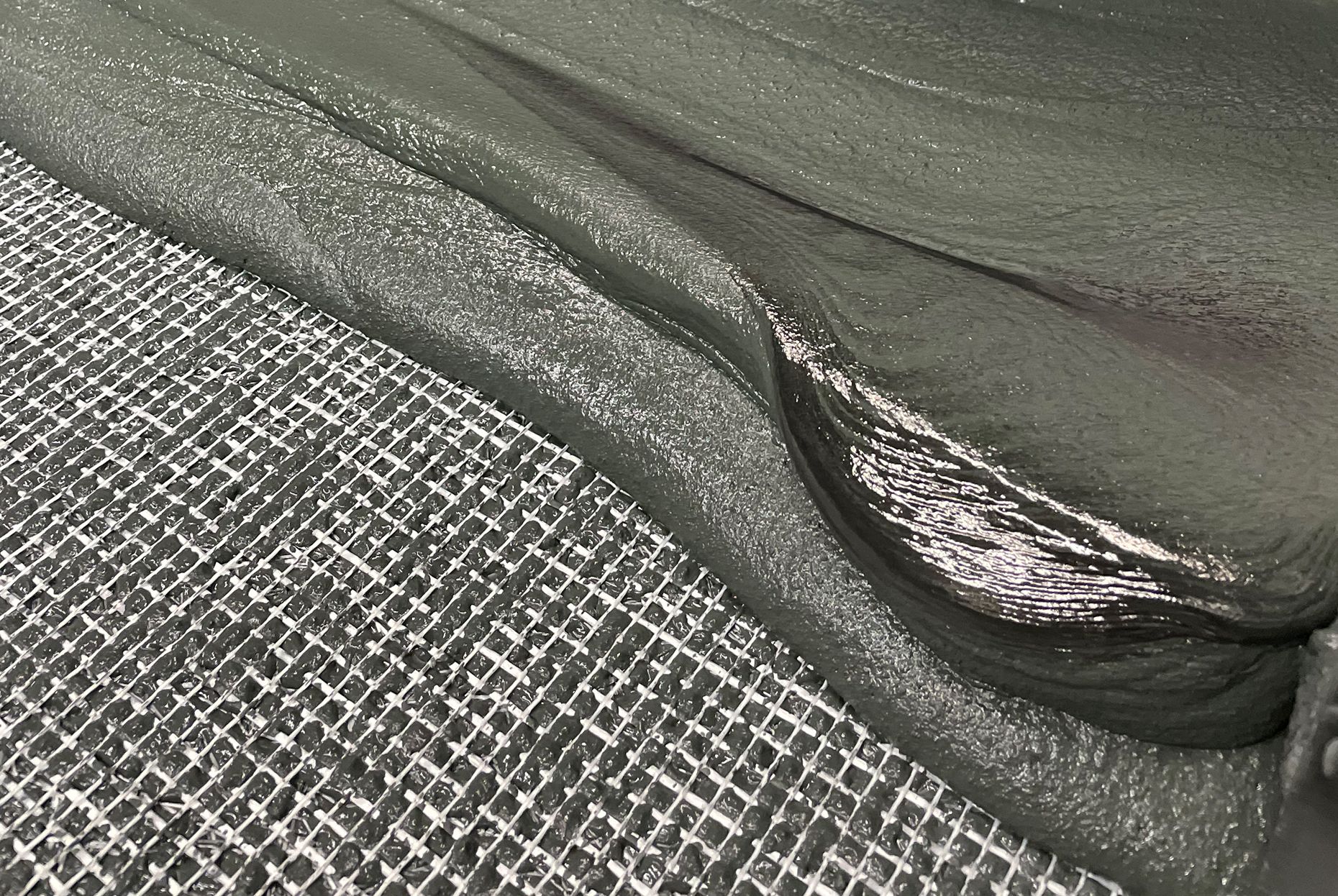

The lifecycle of buildings must increase, not only through converting and revitalizing existing buildings, but also through more durable building materials. A model for this is the opus caementicium, the cast masonry used by the Romans. The Romans added natural pozzolana - volcanic ash, trass, and similar minerals - as a binder, which gave the material a durability that often exceeds that of modern concrete. Driven by the desire to offer customers suitable products for the journey to climate change, Rieder developed a world first: CO₂-reduced facade elements made of glassfibre reinforced concrete.

Prefabrication & serial construction

Progress without innovation is not possible, which is why we are constantly evolving and investing in the systematization of facade construction, which allows for enormous time and resource savings.

Economical complete solution

We offer our customers numerous services such as digital planning tools, high-quality prefabrication, and effective installation solutions. Weather-independent prefabrication in the factory and a high degree of prefabrication ensure a high quality standard, rapid on-site installation, and efficient construction processes. The elements can be cut, pre-drilled, cleaned, and flipped if necessary at our factory. Installation of the substructure of the elements is also possible. The prefabricated modules are simply hooked and finely adjusted on the construction site.