Homepage

Facade elements made of glassfibre reinforced concrete

Rieder's products utilise raw materials from nature, creating an authentic, honest material character. Concrete has a familiar and lively essence. The elements, only 13 mm thin, allow for ample flexibility in designing building envelopes

This is what sets our products apart

Our products

Natural colours, vibrant surfaces, and exciting textures give our products their uniqueness.

The authentic colours blend well into landscapes and correspond with nature and the environment. Colour variations within a colour tone are intended and enhance the liveliness of the building material, concrete. Each colour is available in three surfaces. Additionally, various textures add liveliness and depth to each facade.

„We don’t just want to talk; for the ecological transition to succeed we need to take action.“ Wolfgang Rieder

Rieder was the first manufacturer of glassfibre reinforced concrete facades to voluntarily publish a sustainability report. In the Green Report, the company critically examined itself and scrutinised various areas of its operations. The report was prepared in accordance with the international standards of the Global Reporting Initiative (GRI).

Easy handling during the installation of ventilated facades

Whether visible or concealed fastening, we have the right solution for all requirements. Rieder is happy to accompany you from design to completed facade and ensure that the end result meets all standards.

concrete skin – no limits to individual architecture

The large-format panels pull smoothly over buildings, corners and edges like a skin and create a unique material flow. The elements with a thickness of only 13 mm open up great freedom for the design of individual facades.

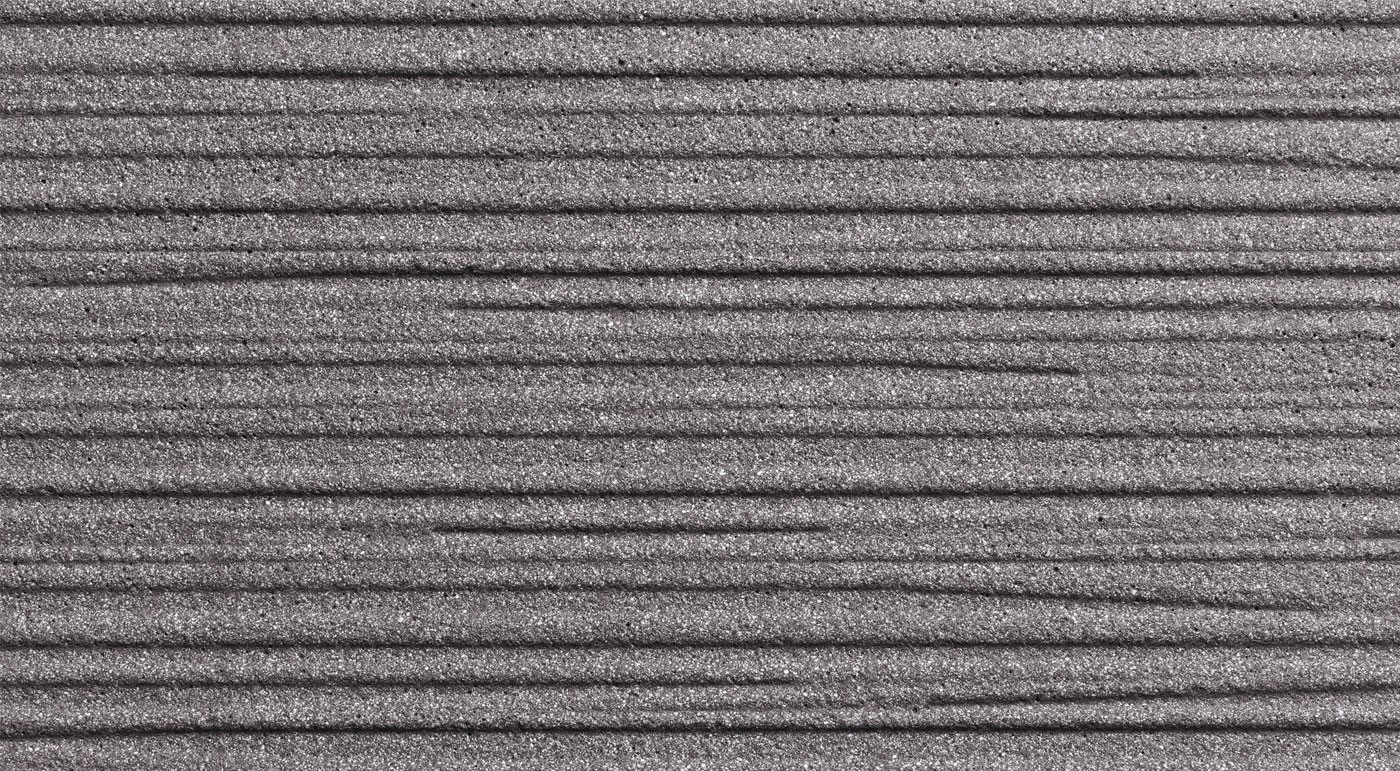

öko skin – facade slats with lively interplay of colour

The narrow facade slats create a lively appearance through various surfaces with just one hue. Their weather resistance provides a significant advantage over wooden slats. The natural look remains preserved.

formparts – monolithic formed parts

The 3D elements not only impart a unique design character, but also serve as refined visual and sun protection. Due to their low weight, they are also excellent for the restoration of existing buildings.

Inspiration

All projectsRieder Facades operates internationally and offers customers a large network. With 3 locations, as well as sales partners in over 50 countries, the innovative concrete products are used worldwide.